Artwork Guidelines

We have prepared the following guide to assist you with your electronic file preparation and submission. If you have a specific problem that is not covered in this guide, or have other questions, please feel free to contact us. Improperly prepared files can cause delays in manufacturing.

Basic file requirements

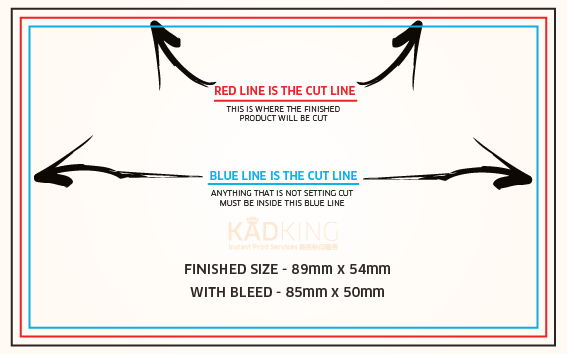

►Bleeds: all files must have at least 2mm to 6mm (depends on products) bleed on each side.

►Live Area: keep all critical text and artwork inside the trim at least 2mm to 6mm (depends on products).

►Colors: supply your files in CMYK color mode (not pantone), total color not exceed 220 in total.

►Resolution: 300 dpi.

►Fonts: fonts must converted to curves/outlines.

►Transparencies: flatten all transparencies.

►File Types: PDF, EPS, TIFF or JPEG.

Guidelines

How to Setup Mask Files

Black areas represent where you want the finish to be located and white means no finish will be applied.

For example, if your project contains hot stamping and spot uv, you must provide separate mask files for each finish.